imagine if your PLC 5 or other LEGACY EQUIPMENT failed now

ready to modernize?

Equipment failures with no replacement get old fast.

Start your PLC 5, SLC 500, and other migrations now.

Rockwell Automation has officially ended support for RSLogix 5 software and PLC 5 controllers. Ready to take advantage of the new features and technology offered by the latest equipment? We can work with you to plan your PLC 5, SLC 500, or other legacy migrations. Avoid the stress and financial impact of a failure and lost production by proactively starting your upgrades.

Why Upgrade Equipment That Still Works?

Quantify the Cost of a Failure

Consider the financial impact of NOT upgrading your PLC 5, SLC 500, or other legacy equipment:

- Does the legacy equipment control critical manufacturing processes?

- What will the financial impact be if a replacement is not readily available?

- What other business impacts could result from extended downtime?

Address Issues with Old Controls and Equipment

- Production reliability issues

- Higher failure risk

- Replacement difficulty

- Increasing costs

- Limited functionality/unsupported platforms

- Compliance challenges

- Cybersecurity gaps

- Integration issues/limited visibility

Reduce Risk and Achieve Results

- Eliminate the risks of obsolete systems

- Preserve your investment in existing applications

- Utilize the advantages of modern platforms

- Enable you to move forward with digital transformation

- Allow you to share data between your plant floor and ERP system

- Comply with new cybersecurity standards

- Achieve better reliability and often enhanced production capacity

Ready to Modernize?

Decide the Scope of Your Upgrade

Typical legacy equipment reaching end-of-life:

- Programmable Logic Controllers (PLC) processors

- I/O racks and I/O cards

- Human-Machine Interfaces (HMIs)

- Variable frequency drives (VFDs)

- Servo controllers

- Plant floor communication network

Map Out Your Upgrade Strategy

- Decide your hardware migration strategy

- Select your software upgrade path

- Determine the order of your equipment migrations

- Group the upgrades into project phases

Get Assistance from Cates Experts

Complimentary Assessment Call

- Discuss your current equipment status, migration path, priorities and concerns

- Our goal is to guide and support you through the upgrade process

- Schedule your System Analysis — based on the size and complexity of your system we’ll determine if it can be completed remotely or if a site visit is required

Complimentary On-Site or Remote

System Analysis

- We’ll analyze your system and provide a hardware assessment, replacement cost and proposed schedule

- For a remote analysis we’ll ask you to upload photos and other information prior to the call to ensure we develop a complete perspective of your system

Our Migration Experience

- We’ve done 100s of successful migrations

- PLC Migration: PLC-5, PLC-2, SLC-500, Modicon, Mitsubishi

- Square D, Provox, HMI, Panelview

Proven Methods

- Reusing I/O and wiring

- Shadowing operation of existing systems

- Rapid cut-over to minimize downtime while installing and commissioning new systems

Map Out Your PLC-5 Migration to ControlLogix

Planning Ahead is Critical

Scheduled PLC-5 upgrades can take weeks or months depending on I/O replacement level, software integration and available downtime.

Increase Scheduling Options

Planned conversions can be done over time and at your convenience to satisfy ongoing production schedules.

Reduce Cost, Risk and Stress

Planned migrations are less expensive and reduce the risks associated with upgrading an entire facility at once.

Get Expert Assistance from Cates

We’ve done 100s of successful conversions

PLC-5 System

Conversions

1771 Series

Chassis Conversions

I/O Points

Migration Expertise Across Industries

Food and

Beverage

Building

Materials

Material

Handling

Product

Manufacturing

Water and

Wastewater

Oil and

Gas

Experience with Large Migrations

Using conversion kits and rewire swing arms, our engineers have done complex upgrades for Fortune 500 firms with tight deadlines.

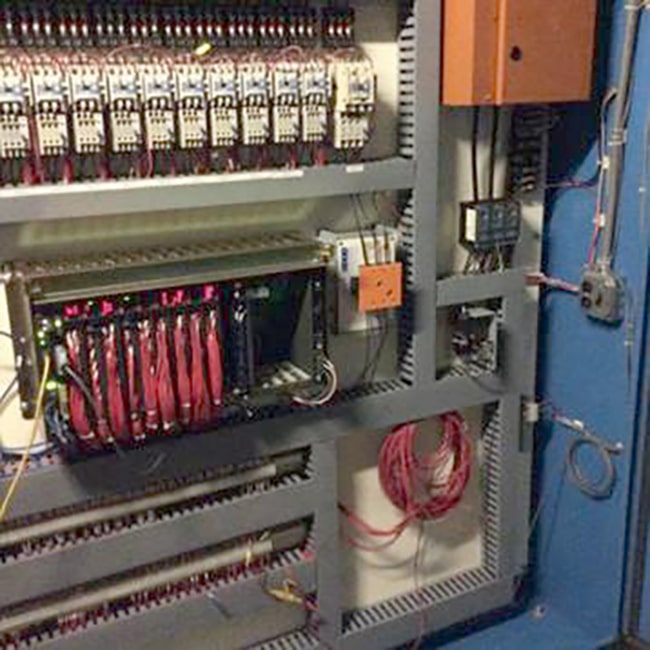

Before PLC-5 Migration

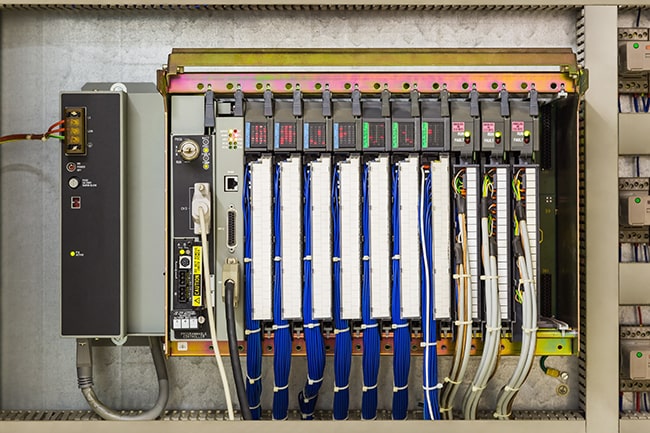

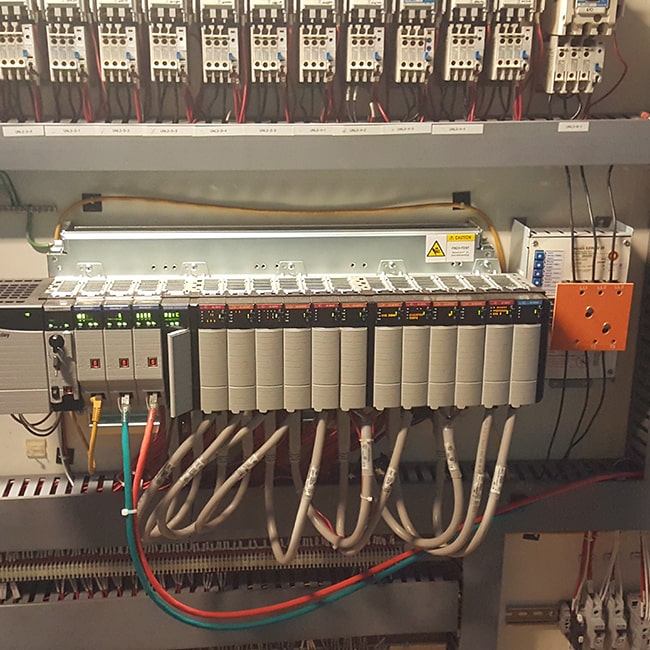

After PLC-5 Migration

Attention to Schedule and Budget

Our experience allows us to meet your migration plan specifications and schedule, or to help you develop a plan to meet your schedule and budget.

Complimentary Services

Discuss your upgrade path with our experts and receive a complimentary remote or on-site system analysis. Whether your project is large or small we’re here to help at whatever points you need assistance.

Start Planning Your Upgrade Today

Information Request

Email us your

PLC-5 migration questions.

Talk to Our Experts

Call us today to discuss

your PLC-5 upgrade.